Nieuws

Menu

Contact

Putting your VISION to work with SOLUTIONS that fit.

Home

Producten

Onze afspraken

Disclaimer

Algemeen

Het onderstaande is van toepassing op de webpagina. Door de webpagina te gebruiken stemt u in met deze disclaimer.Privacy verklaring

U kunt deze website bezoeken zonder ons mee te delen wie u bent of enige informatie over uzelf te verschaffen. Er zijn echter situaties waarbij wij informatie van u nodig hebben om bijvoorbeeld met u te corresponderen, een reservering te plaatsen dan wel een inschrijving te verwezenlijken. Wij streven ernaar u dat te allen tijde te laten weten voordat wij persoonlijke informatie via internet verzamelen.

Deze website houdt door middel van een teller het aantal bezoekers bij, de websites waar zij van afkomstig zijn en via welke provider men toegang heeft tot het internet. De resultaten worden uitsluitend in geaggregeerde en in niet tot individuele personen herleidbare vorm gebruikt.Verzamelde (persoons)gegevens worden niet aan derden verkocht of ter beschikking gesteld. Dit behoudens speciale omstandigheden, bijvoorbeeld indien wettelijk vereist. Tevens kunt u op ieder gewenst moment verzoeken uw gegevens uit onze bestanden te laten verwijderen

Uitsluiting van aansprakelijkheid

Alle informatie op deze webpagina is bedoeld voor persoonlijk gebruik. Aan de informatie kunnen geen rechten worden ontleend. Wijzigingen en typefouten worden voorbehouden. Wij spannen ons in om de informatie op deze webpagina zo volledig en nauwkeurig mogelijk te laten zijn. Klerk Technical Solutions aanvaardt geen enkele verantwoordelijkheid voor schade op welke manier dan ook ontstaan door gebruik, onvolledigheid of onjuistheid van de aangeboden informatie op deze website.Beschikbaarheid

De informatie en aanbevelingen op deze website kunnen zonder voorafgaande waarschuwing of kennisgeving worden gewijzigd. Wij spannen ons in om deze webpagina zo veel mogelijk beschikbaar te stellen, maar wij aanvaarden geen enkele aansprakelijkheid voor eventuele gevolgen van (tijdelijke) niet-beschikbaarheid.Auteursrechten en intellectuele eigendomsrechten

Het auteursrecht op deze website berust bij Jonkman International Services of bij derden welke met toestemming dit (beeld)materiaal beschikbaar hebben gesteld aan Jonkman International Services. Vermenigvuldiging in wat voor vorm dan ook is alleen toegestaan na voorafgaande toestemming door Jonkman International Services.Cookies

Jonkman International Services gebruikt cookies om statistieken te meten in Google Analytics.

Wat zijn cookies?

Een cookie is een eenvoudig klein bestandje dat met pagina's van deze website wordt mee gestuurd en wordt opgeslagen op de harde schijf van uw computer. U kunt cookies uitzetten via uw browser. Via onze site wordt ook een cookie geplaatst van Google voor het gebruik van Google Analytics. Wij gebruiken Google Analytics om bij te houden hoe gebruikers de website gebruiken en om zo de website te optimaliseren.Voorwaarden

Complete systems built to your specifications

From start to finish, we take care of every stage of the laundry process. Our customer’s wished and specific demands are all taken into account. The easy-of-use of our systems is well-known and highly valued by our customers throughout the world. While our user-training ensures smooth acceptance by our laundry operators. After all, it is people who work with the systems.

Full collaboration with the customer

As you are fully aware, no laundry system stands on its own. The type of linenoperation, the machinery used, and the building where the laundry operation takes place require a customized design. That’s why our policy is to have a close working relationship with our customers in order to determine the design from the first lines onwards.

We also take into consideration that the way of operation in each country differs, not only by law, but also from labor point of view. So it is of paramount importance that, together with our customers we achieve the most suitable logistic design. We take care of that, and more.

‘State-of-the-art’ control systems

Our ‘state-of-the-art’ control systems form a fundamental part of the installation and are extensively tested before commissioning. The control systems are also made in close collaboration with our customers. The connectivity of the control systems in a network guarantees optimum harmonization of each and every part in the production process, so stagnations and insufficient use of the system’s capacity are avoided. The advanced possibilities of our control systems feature an additional saving in labour capacity and an enhanced production load. Effectiveness is the keyword here! Our control system guarantee a truly efficient usage of the installation.

Our control system allow the operators to manage the logistical flow directly with user-friendly control touch terminals which are added to a network. This enables operators to be directly involved in the laundry process. More than twenty years of experience and the added know-how of all of our customers worldwide have given us unparalleled expertise in the field of logistic systems. No matter how large or complex.

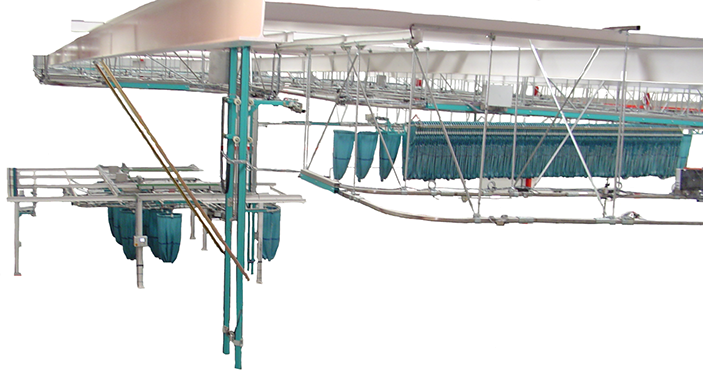

Sorting systemen

Modular and reliable

√ Sorting out multiple customers in one sorting bin

√ Combining small batches together at a customerchange

√ Scalable solutions for multiple groups of sorting bins

√ Multiple sorting templates

√ Reliable and secure data recording and storage

√ Generating production statistics

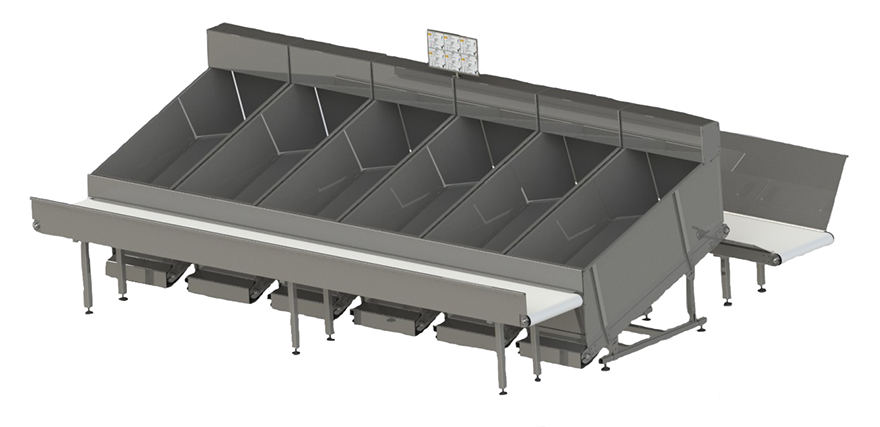

Sorting bins

For medium to large companies which have a lot of different kind of articles often sorting bins will be used. With this system, the linen is sorted out directly into stainless steel bins which are opened automatically after the set weight is reached or the quantity is reached. The laundry is transported on a belt conveyor, which is positioned under or behind the sorting bins, into an empty bagcontainer. In time, this means that after about 8 seconds the sorting bin is emptied and can be used again for sorting out the linen.

The benefits for you at a glance:

√ Suitable for large volumes with a lot of different kind of articles

√ Maximum number of sorting positions per sorter

√ Maximum continuity by short discharge time of the sorting bins

√ Clear visualization of weight, article, status, etc.

√ Automatic loading of one or more sorting position (automatic passage)

Display

To give the user a clear overview in which sorting bin which article must be sorted out, several displays are placed at the sorting bins. Depending on the setup, one display per one or two sorting bins is placed. Plain and simple. The displays show very clearly per sorting bin:

√ Position number

√ Weight and set weight

√ Article and customer

√ Colorindication for weight and status

Tables and templates

In order to make the use of the sorting bins as user-friendly as possible, tables and templates are used. The tables consist of an article table and a customer table. In these tables per article and customer data can be entered which will be used throughout the whole installation. The sorting templates can be filled in according to your own requirements. You can create for one customer one or more sorting templates. Each sorting template links an article to each sorting bin. Once the sorting templates are set up, its use is simple and fast.

And of course you have more advantages:

√ Sorting out multiple customers in one sorting bin

√ Combining small batches at a custmer change

√ Scalable solutions for multiple groups of sorting bins

√ Clear overview on the screen

√ Generating production statistics